The Separation Process: How a Gravity Separator Works

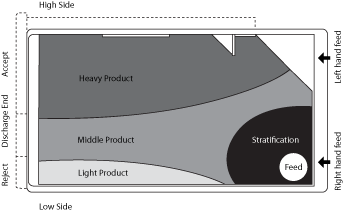

Stratification

From an inlet with an adjustable feed rate, the material is fed onto the gravity separator’s inclined reciprocating grading deck, which normally has a special woven wire mesh surface, except for extremely fine products, when a specialist fabric deck is used.

High volume, low pressure air is passed through the mesh from the fan, the amount of air available is readily adjusted to suit the product being processed. This adjustment is to ensure that the lighter product is lifted to the top of the material and the heavier product remains on the surface of the grading deck, resulting in stratification of product.

Separation

Due to the reciprocating motion of the inclined deck the heavy product will walk uphill to the highest side, whilst the lighter product will drift down towards the low side.

Simple adjustments in end tilt / side tilt / deck speed and volume of air passed through the product whilst the machine is running will dictate the nature of the separation and the throughput.

On Crown Gravity Separators all adjustments are readily and simply made whilst the machine is in use: this enables a combination of control adjustments to result in a very fine separation at the end of the machine, where the split will be made with adjustable knives or sliding chutes.